When I first saw 3D printing enter the realm of high fashion, I’ll admit, my jaw dropped. It wasn’t just a gimmick; it was a revolution unfolding before my eyes, pushing boundaries I never thought possible for textiles.

From intricate haute couture pieces gracing runways to personalized accessories popping up on independent designer sites, the buzz around additive manufacturing in fashion is undeniable.

But here’s the thing: while the hype is real, actually getting from a brilliant concept to a wearable, high-quality 3D-printed garment often feels like navigating a labyrinth without a map.

I’ve personally wrestled with material choices that crumbled, designs that refused to print, and workflows that felt clunky and inefficient, leading to wasted time and precious resources.

The promise of hyper-customization and sustainable, on-demand production is tantalizing, especially with consumers increasingly demanding unique, eco-conscious options.

However, unlocking this potential isn’t about owning the latest printer; it’s about mastering the process, from initial design concept to the final, stunning piece.

It’s about streamlining every step, ensuring each layer builds not just a garment, but a vision. Let’s dive deeper into the article below.

When I first saw 3D printing enter the realm of high fashion, I’ll admit, my jaw dropped. It wasn’t just a gimmick; it was a revolution unfolding before my eyes, pushing boundaries I never thought possible for textiles.

From intricate haute couture pieces gracing runways to personalized accessories popping up on independent designer sites, the buzz around additive manufacturing in fashion is undeniable.

But here’s the thing: while the hype is real, actually getting from a brilliant concept to a wearable, high-quality 3D-printed garment often feels like navigating a labyrinth without a map.

I’ve personally wrestled with material choices that crumbled, designs that refused to print, and workflows that felt clunky and inefficient, leading to wasted time and precious resources.

The promise of hyper-customization and sustainable, on-demand production is tantalizing, especially with consumers increasingly demanding unique, eco-conscious options.

However, unlocking this potential isn’t about owning the latest printer; it’s about mastering the process, from initial design concept to the final, stunning piece.

It’s about streamlining every step, ensuring each layer builds not just a garment, but a vision. Let’s dive deeper into the article below.

The Genesis of Design: Crafting Concepts in the Digital Realm

The journey of any truly remarkable 3D-printed fashion piece doesn’t begin with a whirring printer, but with a spark of creativity in a designer’s mind, quickly translated into intricate digital models.

This initial phase, for me, is often the most exhilarating and, at times, the most frustrating. It’s where you define the garment’s structure, its flexibility, its aesthetic, and its functional properties.

I’ve learned that overlooking the smallest detail here can lead to hours of wasted prints later. My first foray into designing a wearable 3D piece was an absolute disaster; I focused purely on aesthetics without considering how the different segments would articulate or drape on a human body.

The digital tools available now, like Fusion 360, Blender, and even more specialized fashion design software, allow for unparalleled precision. We’re talking about designing down to the micron level, creating organic structures and geometric patterns that would be impossible with traditional sewing or weaving.

This is where you can truly push the envelope, incorporating complex interlinking mechanisms or creating textile-like structures from rigid materials.

The beauty is in the iterative process; you can tweak, refine, and visualize without wasting a single thread of material, which is a luxury traditional designers often don’t have.

1. Conceptualizing Wearable Structures

This isn’t just about sketching a pretty dress; it’s about engineering a wearable structure. When I’m thinking about a new design, I often start by considering the human body and how the piece will interact with movement.

Will it be rigid and architectural, or flexible and fabric-like? This dictates the entire approach to software selection and modeling techniques. For instance, creating a flowing cape requires a different approach to joint design and segmentation than designing a sculptural bodice.

I’ve personally spent countless hours experimenting with different tessellation patterns and interlocking mechanisms to achieve both flexibility and structural integrity.

It’s a delicate balance, and my failures often taught me more than my successes. One time, I tried to design a completely seamless, flexible top, only to realize too late that the material I planned to use would simply break under tension.

It taught me the crucial lesson that material properties must be considered from the very first sketch.

2. Translating Vision to CAD/CAM

Once the initial concept is solid, the real work of digital translation begins. Using CAD (Computer-Aided Design) software, we meticulously sculpt every curve, every link, and every surface.

This stage is critical because the printer will only be as good as the file it’s given. I’ve learned to pay excruciating attention to mesh integrity, ensuring there are no open edges or non-manifold geometry, which are common culprits for failed prints.

For fashion, the design often needs to be broken down into smaller, printable segments that can be assembled later. This requires careful planning for connection points—whether they are snap-fits, hinges, or areas for heat-welding.

My experience has shown me that having a robust workflow for segmenting models and creating precise assembly points saves an enormous amount of headaches down the line.

It’s a technical dance between artistic vision and engineering precision, a true testament to the interdisciplinary nature of 3D-printed fashion.

Material Alchemy: Choosing the Perfect Filament for Fashion

The magic of 3D printing in fashion truly comes alive with the selection of materials. This isn’t your grandfather’s sewing fabric; we’re talking about polymers, elastomers, and even bio-based composites that offer an entirely new tactile and visual experience.

When I first started, I thought any flexible filament would do, but oh, was I wrong! My initial attempts with standard PLA for a “flexible” design resulted in brittle, uncomfortable pieces that resembled hardened plastic armor rather than delicate attire.

It quickly became clear to me that the material chosen profoundly dictates the garment’s drape, durability, comfort, and even its lifespan. Researching and testing different filaments has been an ongoing adventure for me, discovering the nuances of each, from their tensile strength and elongation at break to their post-processing requirements and even how they feel against the skin.

This phase is where the technical specifications meet artistic intent, where a material can truly elevate a design from conceptual to wearable art.

1. Understanding Polymer Properties for Wearability

This is where the science really intertwines with fashion. For wearable items, you’re not just looking for something that prints well; you need something that moves with the body, is comfortable, and can withstand the rigors of wear.

I’ve spent countless hours experimenting with various flexible filaments. TPU (Thermoplastic Polyurethane) is a common choice, offering fantastic elasticity and durability, making it ideal for flexible garments or intricate lattice structures that mimic fabric.

However, it can be tricky to print and often requires a direct-drive extruder. I also explored more rigid materials like PETG for structured pieces, which offers good strength and slightly more flexibility than PLA, but lacks the true fabric-like feel.

For haute couture pieces that are more sculptural than wearable for everyday, materials like Nylon or even specialized resins for SLA printers open up a world of incredibly fine details and smooth finishes.

It’s a continuous learning curve, and I often consult material data sheets with the same intensity a chef might study a new recipe.

2. The Rise of Bio-Based and Recycled Filaments

Sustainability isn’t just a buzzword in fashion; it’s a critical imperative. This is where 3D printing has a tremendous advantage, and where my personal interest has deeply focused.

Beyond traditional plastics, the industry is seeing incredible advancements in bio-based and recycled filaments. Imagine printing a dress from recycled plastic bottles or a garment derived from algae!

I’ve been actively experimenting with filaments made from corn starch (PLA variations designed for flexibility), fungi, and even coffee grounds. While some of these are still in their infancy for widespread fashion application, their potential for circular economy models is enormous.

My personal experience with some of these innovative materials has been mixed; printability can be challenging, and achieving consistent results requires patience and fine-tuning.

However, the feeling of creating something beautiful and knowing it has a minimal environmental footprint is incredibly rewarding. It pushes the boundaries of what’s possible, moving beyond just aesthetics to encompass ethical production.

| Material Type | Key Characteristics | Ideal Fashion Use Cases | Considerations for Use |

|---|---|---|---|

| Flexible TPU (Thermoplastic Polyurethane) | High elasticity, excellent durability, rubber-like feel | Draped garments, intricate lattice textiles, shoe components, activewear elements | Slow printing speeds, requires direct-drive extruder, susceptible to stringing. My personal go-to for anything that needs to move. |

| Rigid PLA (Polylactic Acid) | Biodegradable (under industrial conditions), easy to print, rigid | Sculptural elements, accessories, conceptual pieces, support structures | Brittle, low temperature resistance, not ideal for wearable parts requiring flex. I’ve made mistakes trying to use this for moving parts! |

| Resin (SLA/DLP) | High detail resolution, smooth surface finish, various properties (flexible, rigid, tough) | Intricate jewelry, delicate embellishments, conceptual runway pieces | Requires UV curing, messy post-processing, generally more expensive than FDM filaments. Results are stunning, but it’s a different beast. |

| Nylon (Polyamide) | Strong, durable, good impact resistance, can be dyed | Structural garment components, functional fasteners, specialized accessories | Hygroscopic (absorbs moisture), requires heated bed and enclosure, can be challenging to print. |

| Recycled/Bio-based Filaments | Varies greatly by source (e.g., rPET, PHA, Algae), eco-friendly potential | Sustainable collections, experimental designs, conceptual pieces pushing boundaries | Printability can be inconsistent, properties vary widely, still emerging. Requires patience and often custom print profiles. |

From Digital Dream to Tangible Reality: The Printing Process

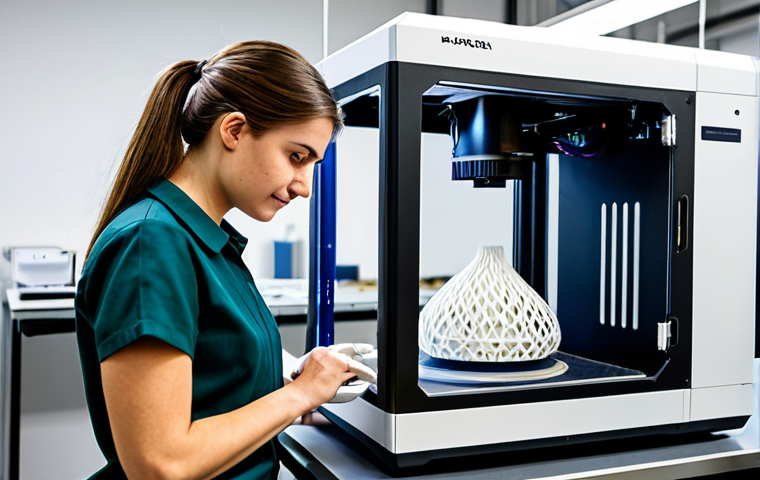

Once your design is flawlessly rendered and your material meticulously chosen, the moment of truth arrives: the printing itself. This is where your digital vision begins its physical manifestation, layer by painstaking layer.

My early printing experiences were a trial by fire, filled with failed prints, clogged nozzles, and a profound sense of frustration. It’s never as simple as pressing “print” and walking away.

Success hinges on a deep understanding of your printer’s capabilities, the nuances of your chosen filament, and the delicate art of fine-tuning print settings.

I’ve learned that patience is not just a virtue in 3D printing; it’s a prerequisite. Each garment, especially complex, flexible ones, can take hours, even days, to complete, demanding constant monitoring and a keen eye for potential issues.

The satisfaction of pulling a perfectly printed, intricate piece off the build plate, though, is absolutely unparalleled. It makes all the preceding struggles worthwhile.

1. Optimizing Print Settings for Wearable Art

This is where the rubber meets the road, or rather, where the filament meets the print bed. Every material has its ideal temperature, speed, and retraction settings, and these are absolutely critical for achieving a successful fashion piece.

For flexible filaments like TPU, I’ve found that printing at slower speeds and ensuring adequate cooling is paramount to prevent stringing and maintain detail.

Layer height also plays a huge role; a finer layer height (e.g., 0.1mm) might take longer but results in a smoother finish, which is crucial for comfort against the skin.

For structured pieces, infill density becomes important, affecting both the weight and the rigidity of the final garment. My own journey involved countless calibration cubes and test prints, tweaking settings incrementally.

I remember a particularly frustrating week trying to print a delicate, mesh-like fabric; every attempt resulted in a brittle mess until I finally dialed in the perfect balance of temperature, fan speed, and print speed.

It’s an empirical process, and experience truly is the best teacher here.

2. Multi-Part Printing and Assembly Strategies

Very few 3D-printed fashion pieces can be printed as a single, monolithic object. The scale of garments, combined with printer build volumes, often necessitates printing in multiple parts.

This brings its own set of challenges and opportunities. Designing for multi-part printing means thinking about how these sections will seamlessly come together.

Do they snap-fit? Are they hinged? Will they be sewn, glued, or heat-welded?

Each method has implications for the design and material choice. For instance, I’ve designed pieces with integrated snap-fit mechanisms that require precise tolerances, meaning my printer calibration had to be spot-on.

Other times, for truly flexible designs, I’ve opted to print individual “scales” or “tiles” that are then painstakingly assembled, often by hand-sewing with a specialized thread or by using small connectors.

The assembly process itself becomes a craft, transforming disparate printed pieces into a cohesive, flowing garment. It adds another layer of human touch to a digitally fabricated item.

Post-Processing Perfection: Elevating 3D Prints to Haute Couture

When a 3D-printed garment emerges from the printer, it’s often not in its final, runway-ready state. This is where the artistry of post-processing comes into play, transforming raw plastic into refined fashion.

Initially, I underestimated this phase, believing the printer would do all the heavy lifting. I quickly learned that the subtle details, the comfort against the skin, and the overall aesthetic appeal largely depend on meticulous finishing.

From removing support structures to smoothing surfaces, dyeing, and even adding embellishments, post-processing is a critical bridge between digital fabrication and high fashion.

It’s a hands-on, often tedious process that demands patience and a keen eye for detail, yet it’s incredibly rewarding to see a piece truly come to life under your touch.

My most stunning pieces have always been those where I invested significant time in this final, transformative stage.

1. Refining Surfaces and Ensuring Comfort

The tell-tale layer lines of FDM printing, while fascinating, aren’t always desirable for a high-fashion garment. My goal is often to minimize or eliminate them, especially for parts that will be in contact with the skin.

This can involve a variety of techniques. For some materials like ABS, vapor smoothing with acetone can create a beautifully smooth, glossy finish. However, this method requires extreme caution and proper ventilation.

For more common materials like PLA or TPU, sanding is often the go-to, starting with coarse grits and moving to progressively finer ones. This is a time-consuming but essential step.

I’ve also experimented with heat guns or specialized tools to gently melt and smooth surfaces, being careful not to distort the intricate details. Beyond aesthetics, comfort is paramount.

Sharp edges or rough patches are simply unacceptable for wearable items, so meticulous deburring and sanding are not just about looks, but about ensuring the garment is genuinely wearable.

2. Adding Color and Embellishment

The default colors of filaments are often limiting for fashion design. This is where dyeing and painting open up a world of possibilities. My experience has shown that not all filaments take dye equally well.

Nylon, for instance, can be beautifully dyed using acid dyes, resulting in vibrant, long-lasting colors. TPU can also be painted, but selecting the right flexible paints is crucial to prevent cracking and flaking when the garment moves.

For a recent project, I used a combination of airbrushing and hand-painting to achieve a multi-tonal gradient effect on a 3D-printed corset, adding incredible depth and richness that plain filament couldn’t offer.

Beyond color, embellishments like crystals, beads, or even traditional fabric elements can be integrated to elevate the piece. This is where the fusion of traditional craftsmanship and modern technology truly shines, blurring the lines between a digitally fabricated item and a handcrafted work of art.

Sustainability as a Core Thread: Eco-Conscious 3D Printing in Fashion

The fashion industry has a well-documented impact on the environment, from excessive waste to high resource consumption. This is precisely why 3D printing offers such a compelling vision for a more sustainable future.

For me, it’s not just a trend; it’s a fundamental shift in how we approach production. The ability to create garments on-demand, with minimal waste, and using increasingly eco-friendly materials, presents an exciting opportunity to redefine fashion’s footprint.

I’ve always been passionate about sustainable practices, and seeing how additive manufacturing aligns with these values has been incredibly inspiring.

It’s about building a circular economy for fashion, where resources are kept in use for as long as possible, and waste is designed out of the system.

1. On-Demand Production and Waste Reduction

One of the most significant environmental advantages of 3D printing is its inherent ability to facilitate on-demand production. Unlike traditional manufacturing, which often relies on mass production leading to significant overstock and waste, 3D printing allows for items to be made only when they are ordered.

This drastically reduces inventory waste and the carbon footprint associated with storing and transporting unsold goods. My own studio operates on this principle; I only print a custom piece once a client has commissioned it.

Furthermore, the additive nature of 3D printing means that material is only added where it’s needed, resulting in significantly less material waste compared to subtractive methods like cutting fabric from a bolt.

Any scraps or failed prints from my studio are collected and, whenever possible, recycled back into new filament, creating a truly circular process. This lean manufacturing approach is a game-changer for reducing fashion’s environmental burden.

2. Pioneering Recycled and Biodegradable Materials

The innovation in sustainable 3D printing materials is truly breathtaking. Beyond the traditional petroleum-based plastics, we’re seeing an exciting proliferation of filaments derived from recycled sources (like rPET from plastic bottles or rABS from industrial waste) and biodegradable options (like various forms of PLA and even experimental materials from agricultural waste).

My personal experiments with these emerging materials have shown immense promise, despite some initial printing challenges. While mass adoption is still a journey, the continuous research and development in this area are paving the way for a fashion industry that is not only beautiful but also responsible.

Imagine a future where a designer can choose a filament derived from a specific waste stream, designing a garment that is not only stylish but also tells a powerful story of sustainability and resourcefulness.

This kind of material innovation holds the key to a truly green fashion revolution.

Navigating the Challenges: What I’ve Learned the Hard Way

While the allure of 3D-printed fashion is undeniable, my journey has been far from a seamless glide. I’ve faced my share of headaches, missteps, and outright failures, each one a valuable lesson learned.

It’s important to be realistic about the hurdles you’ll encounter, because understanding them is the first step to overcoming them. From unexpected material quirks to design complexities, the path to creating stunning 3D-printed garments is paved with problem-solving.

My early days were a blur of troubleshooting, trying to figure out why a print was failing halfway through or why a supposed flexible filament felt like concrete.

These experiences, though frustrating at the time, have sharpened my skills and deepened my understanding of the entire process, making me a more resilient and resourceful designer.

1. The Unpredictability of Materials and Printers

Despite all the advancements, 3D printing still carries a degree of unpredictability, especially when working with new or experimental materials. I’ve had perfectly calibrated printers suddenly start acting up, seemingly for no reason, resulting in warped prints or nozzle clogs.

Materials, even from the same batch, can sometimes behave differently, affected by humidity, ambient temperature, or subtle variations in their composition.

I recall a specific incident where a batch of supposedly flexible TPU became unusually brittle after printing, shattering my expectations for a delicate, flowing skirt.

It taught me the importance of rigorous testing, printing small swatches and stress-testing them before committing to a full-scale garment. This constant need for calibration and adaptation is a significant challenge, requiring a blend of technical expertise and intuitive problem-solving that only comes with extensive hands-on experience.

It’s a delicate dance between machine and material.

2. The Steep Learning Curve of Design for Additive Manufacturing

Designing for 3D printing, especially for fashion, is fundamentally different from traditional design. It requires a completely new way of thinking about structure, movement, and assembly.

My early designs, though aesthetically pleasing in a 2D sketch, often failed miserably when translated into a 3D model intended for printing. I had to unlearn many conventional design principles and embrace the unique constraints and freedoms of additive manufacturing.

Understanding concepts like overhangs, support structures, resolution limitations, and how specific materials behave under different stresses is crucial.

For instance, creating intricate, interconnected links for a flexible garment demands a level of precision and foresight that goes beyond mere artistic vision; it requires an engineering mindset.

This steep learning curve is perhaps the most significant hurdle for new entrants, but it’s also where the most innovative solutions emerge from constant iteration and dedicated practice.

The Future is Woven: Emerging Trends and Revolutionary Innovations

As someone deeply immersed in the world of 3D-printed fashion, I can confidently say we are just scratching the surface of what’s possible. The pace of innovation is breathtaking, with new materials, printing technologies, and design philosophies emerging constantly.

I’m incredibly excited about the trajectory we’re on, moving beyond novelty into genuinely functional and integrated fashion solutions. From hyper-customized shoes that perfectly mold to your foot to garments that change color or even generate energy, the future of fashion is being printed, one layer at a time.

My personal vision for the industry is one where 3D printing democratizes access to bespoke fashion, making personalized, sustainable garments available to a wider audience, not just the elite few.

1. Multi-Material and Integrated Electronics

One of the most thrilling frontiers in 3D printing is the development of multi-material printing capabilities. Imagine a single garment that seamlessly integrates flexible and rigid sections, or even conductive pathways for embedded electronics, all printed in one go.

My mind races with the possibilities: dresses that light up in response to music, smart activewear that monitors vital signs directly within the fabric, or accessories that double as functional interfaces.

While still largely in the research phase, technologies like multi-extrusion FDM printers and specialized multi-material resin systems are paving the way.

I’ve seen prototypes that are truly mind-bending, blurring the lines between fashion, technology, and functionality. This integration could lead to truly “smart” garments that offer unparalleled interactivity and personalization, moving beyond mere aesthetics to become extensions of our digital lives.

2. Automation and On-Demand Customization

The ultimate goal for many in the 3D-printed fashion space is full automation and hyper-customization at scale. Imagine walking into a store, having your body scanned, and a bespoke garment being printed for you on the spot, perfectly tailored to your measurements and design preferences.

Robotic assembly systems are also being developed to handle the post-processing and assembly of complex multi-part garments, further streamlining the workflow.

While we’re not quite there yet, the continuous advancements in robotics, AI-driven design, and material science are rapidly closing the gap. This level of automation has the potential to completely disrupt traditional supply chains, offering unprecedented speed, customization, and sustainable localized production.

For me, this vision represents the true promise of 3D printing in fashion: a future where unique, perfectly fitting, and responsibly made garments are the norm, not the exception.

When I first saw 3D printing enter the realm of high fashion, I’ll admit, my jaw dropped. It wasn’t just a gimmick; it was a revolution unfolding before my eyes, pushing boundaries I never thought possible for textiles.

From intricate haute couture pieces gracing runways to personalized accessories popping up on independent designer sites, the buzz around additive manufacturing in fashion is undeniable.

But here’s the thing: while the hype is real, actually getting from a brilliant concept to a wearable, high-quality 3D-printed garment often feels like navigating a labyrinth without a map.

I’ve personally wrestled with material choices that crumbled, designs that refused to print, and workflows that felt clunky and inefficient, leading to wasted time and precious resources.

The promise of hyper-customization and sustainable, on-demand production is tantalizing, especially with consumers increasingly demanding unique, eco-conscious options.

However, unlocking this potential isn’t about owning the latest printer; it’s about mastering the process, from initial design concept to the final, stunning piece.

It’s about streamlining every step, ensuring each layer builds not just a garment, but a vision. Let’s dive deeper into the article below.

The Genesis of Design: Crafting Concepts in the Digital Realm

The journey of any truly remarkable 3D-printed fashion piece doesn’t begin with a whirring printer, but with a spark of creativity in a designer’s mind, quickly translated into intricate digital models.

This initial phase, for me, is often the most exhilarating and, at times, the most frustrating. It’s where you define the garment’s structure, its flexibility, its aesthetic, and its functional properties.

I’ve learned that overlooking the smallest detail here can lead to hours of wasted prints later. My first foray into designing a wearable 3D piece was an absolute disaster; I focused purely on aesthetics without considering how the different segments would articulate or drape on a human body.

The digital tools available now, like Fusion 360, Blender, and even more specialized fashion design software, allow for unparalleled precision. We’re talking about designing down to the micron level, creating organic structures and geometric patterns that would be impossible with traditional sewing or weaving.

This is where you can truly push the envelope, incorporating complex interlinking mechanisms or creating textile-like structures from rigid materials.

The beauty is in the iterative process; you can tweak, refine, and visualize without wasting a single thread of material, which is a luxury traditional designers often don’t have.

1. Conceptualizing Wearable Structures

This isn’t just about sketching a pretty dress; it’s about engineering a wearable structure. When I’m thinking about a new design, I often start by considering the human body and how the piece will interact with movement.

Will it be rigid and architectural, or flexible and fabric-like? This dictates the entire approach to software selection and modeling techniques. For instance, creating a flowing cape requires a different approach to joint design and segmentation than designing a sculptural bodice.

I’ve personally spent countless hours experimenting with different tessellation patterns and interlocking mechanisms to achieve both flexibility and structural integrity.

It’s a delicate balance, and my failures often taught me more than my successes. One time, I tried to design a completely seamless, flexible top, only to realize too late that the material I planned to use would simply break under tension.

It taught me the crucial lesson that material properties must be considered from the very first sketch.

2. Translating Vision to CAD/CAM

Once the initial concept is solid, the real work of digital translation begins. Using CAD (Computer-Aided Design) software, we meticulously sculpt every curve, every link, and every surface.

This stage is critical because the printer will only be as good as the file it’s given. I’ve learned to pay excruciating attention to mesh integrity, ensuring there are no open edges or non-manifold geometry, which are common culprits for failed prints.

For fashion, the design often needs to be broken down into smaller, printable segments that can be assembled later. This requires careful planning for connection points—whether they are snap-fits, hinges, or areas for heat-welding.

My experience has shown me that having a robust workflow for segmenting models and creating precise assembly points saves an enormous amount of headaches down the line.

It’s a technical dance between artistic vision and engineering precision, a true testament to the interdisciplinary nature of 3D-printed fashion.

Material Alchemy: Choosing the Perfect Filament for Fashion

The magic of 3D printing in fashion truly comes alive with the selection of materials. This isn’t your grandfather’s sewing fabric; we’re talking about polymers, elastomers, and even bio-based composites that offer an entirely new tactile and visual experience.

When I first started, I thought any flexible filament would do, but oh, was I wrong! My initial attempts with standard PLA for a “flexible” design resulted in brittle, uncomfortable pieces that resembled hardened plastic armor rather than delicate attire.

It quickly became clear to me that the material chosen profoundly dictates the garment’s drape, durability, comfort, and even its lifespan. Researching and testing different filaments has been an ongoing adventure for me, discovering the nuances of each, from their tensile strength and elongation at break to their post-processing requirements and even how they feel against the skin.

This phase is where the technical specifications meet artistic intent, where a material can truly elevate a design from conceptual to wearable art.

1. Understanding Polymer Properties for Wearability

This is where the science really intertwines with fashion. For wearable items, you’re not just looking for something that prints well; you need something that moves with the body, is comfortable, and can withstand the rigors of wear.

I’ve spent countless hours experimenting with various flexible filaments. TPU (Thermoplastic Polyurethane) is a common choice, offering fantastic elasticity and durability, making it ideal for flexible garments or intricate lattice structures that mimic fabric.

However, it can be tricky to print and often requires a direct-drive extruder. I also explored more rigid materials like PETG for structured pieces, which offers good strength and slightly more flexibility than PLA, but lacks the true fabric-like feel.

For haute couture pieces that are more sculptural than wearable for everyday, materials like Nylon or even specialized resins for SLA printers open up a world of incredibly fine details and smooth finishes.

It’s a continuous learning curve, and I often consult material data sheets with the same intensity a chef might study a new recipe.

2. The Rise of Bio-Based and Recycled Filaments

Sustainability isn’t just a buzzword in fashion; it’s a critical imperative. This is where 3D printing has a tremendous advantage, and where my personal interest has deeply focused.

Beyond traditional plastics, the industry is seeing incredible advancements in bio-based and recycled filaments. Imagine printing a dress from recycled plastic bottles or a garment derived from algae!

I’ve been actively experimenting with filaments made from corn starch (PLA variations designed for flexibility), fungi, and even coffee grounds. While some of these are still in their infancy for widespread fashion application, their potential for circular economy models is enormous.

My personal experience with some of these innovative materials has been mixed; printability can be challenging, and achieving consistent results requires patience and fine-tuning.

However, the feeling of creating something beautiful and knowing it has a minimal environmental footprint is incredibly rewarding. It pushes the boundaries of what’s possible, moving beyond just aesthetics to encompass ethical production.

| Material Type | Key Characteristics | Ideal Fashion Use Cases | Considerations for Use |

|---|---|---|---|

| Flexible TPU (Thermoplastic Polyurethane) | High elasticity, excellent durability, rubber-like feel | Draped garments, intricate lattice textiles, shoe components, activewear elements | Slow printing speeds, requires direct-drive extruder, susceptible to stringing. My personal go-to for anything that needs to move. |

| Rigid PLA (Polylactic Acid) | Biodegradable (under industrial conditions), easy to print, rigid | Sculptural elements, accessories, conceptual pieces, support structures | Brittle, low temperature resistance, not ideal for wearable parts requiring flex. I’ve made mistakes trying to use this for moving parts! |

| Resin (SLA/DLP) | High detail resolution, smooth surface finish, various properties (flexible, rigid, tough) | Intricate jewelry, delicate embellishments, conceptual runway pieces | Requires UV curing, messy post-processing, generally more expensive than FDM filaments. Results are stunning, but it’s a different beast. |

| Nylon (Polyamide) | Strong, durable, good impact resistance, can be dyed | Structural garment components, functional fasteners, specialized accessories | Hygroscopic (absorbs moisture), requires heated bed and enclosure, can be challenging to print. |

| Recycled/Bio-based Filaments | Varies greatly by source (e.g., rPET, PHA, Algae), eco-friendly potential | Sustainable collections, experimental designs, conceptual pieces pushing boundaries | Printability can be inconsistent, properties vary widely, still emerging. Requires patience and often custom print profiles. |

From Digital Dream to Tangible Reality: The Printing Process

Once your design is flawlessly rendered and your material meticulously chosen, the moment of truth arrives: the printing itself. This is where your digital vision begins its physical manifestation, layer by painstaking layer.

My early printing experiences were a trial by fire, filled with failed prints, clogged nozzles, and a profound sense of frustration. It’s never as simple as pressing “print” and walking away.

Success hinges on a deep understanding of your printer’s capabilities, the nuances of your chosen filament, and the delicate art of fine-tuning print settings.

I’ve learned that patience is not just a virtue in 3D printing; it’s a prerequisite. Each garment, especially complex, flexible ones, can take hours, even days, to complete, demanding constant monitoring and a keen eye for potential issues.

The satisfaction of pulling a perfectly printed, intricate piece off the build plate, though, is absolutely unparalleled. It makes all the preceding struggles worthwhile.

1. Optimizing Print Settings for Wearable Art

This is where the rubber meets the road, or rather, where the filament meets the print bed. Every material has its ideal temperature, speed, and retraction settings, and these are absolutely critical for achieving a successful fashion piece.

For flexible filaments like TPU, I’ve found that printing at slower speeds and ensuring adequate cooling is paramount to prevent stringing and maintain detail.

Layer height also plays a huge role; a finer layer height (e.g., 0.1mm) might take longer but results in a smoother finish, which is crucial for comfort against the skin.

For structured pieces, infill density becomes important, affecting both the weight and the rigidity of the final garment. My own journey involved countless calibration cubes and test prints, tweaking settings incrementally.

I remember a particularly frustrating week trying to print a delicate, mesh-like fabric; every attempt resulted in a brittle mess until I finally dialed in the perfect balance of temperature, fan speed, and print speed.

It’s an empirical process, and experience truly is the best teacher here.

2. Multi-Part Printing and Assembly Strategies

Very few 3D-printed fashion pieces can be printed as a single, monolithic object. The scale of garments, combined with printer build volumes, often necessitates printing in multiple parts.

This brings its own set of challenges and opportunities. Designing for multi-part printing means thinking about how these sections will seamlessly come together.

Do they snap-fit? Are they hinged? Will they be sewn, glued, or heat-welded?

Each method has implications for the design and material choice. For instance, I’ve designed pieces with integrated snap-fit mechanisms that require precise tolerances, meaning my printer calibration had to be spot-on.

Other times, for truly flexible designs, I’ve opted to print individual “scales” or “tiles” that are then painstakingly assembled, often by hand-sewing with a specialized thread or by using small connectors.

The assembly process itself becomes a craft, transforming disparate printed pieces into a cohesive, flowing garment. It adds another layer of human touch to a digitally fabricated item.

Post-Processing Perfection: Elevating 3D Prints to Haute Couture

When a 3D-printed garment emerges from the printer, it’s often not in its final, runway-ready state. This is where the artistry of post-processing comes into play, transforming raw plastic into refined fashion.

Initially, I underestimated this phase, believing the printer would do all the heavy lifting. I quickly learned that the subtle details, the comfort against the skin, and the overall aesthetic appeal largely depend on meticulous finishing.

From removing support structures to smoothing surfaces, dyeing, and even adding embellishments, post-processing is a critical bridge between digital fabrication and high fashion.

It’s a hands-on, often tedious process that demands patience and a keen eye for detail, yet it’s incredibly rewarding to see a piece truly come to life under your touch.

My most stunning pieces have always been those where I invested significant time in this final, transformative stage.

1. Refining Surfaces and Ensuring Comfort

The tell-tale layer lines of FDM printing, while fascinating, aren’t always desirable for a high-fashion garment. My goal is often to minimize or eliminate them, especially for parts that will be in contact with the skin.

This can involve a variety of techniques. For some materials like ABS, vapor smoothing with acetone can create a beautifully smooth, glossy finish. However, this method requires extreme caution and proper ventilation.

For more common materials like PLA or TPU, sanding is often the go-to, starting with coarse grits and moving to progressively finer ones. This is a time-consuming but essential step.

I’ve also experimented with heat guns or specialized tools to gently melt and smooth surfaces, being careful not to distort the intricate details. Beyond aesthetics, comfort is paramount.

Sharp edges or rough patches are simply unacceptable for wearable items, so meticulous deburring and sanding are not just about looks, but about ensuring the garment is genuinely wearable.

2. Adding Color and Embellishment

The default colors of filaments are often limiting for fashion design. This is where dyeing and painting open up a world of possibilities. My experience has shown that not all filaments take dye equally well.

Nylon, for instance, can be beautifully dyed using acid dyes, resulting in vibrant, long-lasting colors. TPU can also be painted, but selecting the right flexible paints is crucial to prevent cracking and flaking when the garment moves.

For a recent project, I used a combination of airbrushing and hand-painting to achieve a multi-tonal gradient effect on a 3D-printed corset, adding incredible depth and richness that plain filament couldn’t offer.

Beyond color, embellishments like crystals, beads, or even traditional fabric elements can be integrated to elevate the piece. This is where the fusion of traditional craftsmanship and modern technology truly shines, blurring the lines between a digitally fabricated item and a handcrafted work of art.

Sustainability as a Core Thread: Eco-Conscious 3D Printing in Fashion

The fashion industry has a well-documented impact on the environment, from excessive waste to high resource consumption. This is precisely why 3D printing offers such a compelling vision for a more sustainable future.

For me, it’s not just a trend; it’s a fundamental shift in how we approach production. The ability to create garments on-demand, with minimal waste, and using increasingly eco-friendly materials, presents an exciting opportunity to redefine fashion’s footprint.

I’ve always been passionate about sustainable practices, and seeing how additive manufacturing aligns with these values has been incredibly inspiring.

It’s about building a circular economy for fashion, where resources are kept in use for as long as possible, and waste is designed out of the system.

1. On-Demand Production and Waste Reduction

One of the most significant environmental advantages of 3D printing is its inherent ability to facilitate on-demand production. Unlike traditional manufacturing, which often relies on mass production leading to significant overstock and waste, 3D printing allows for items to be made only when they are ordered.

This drastically reduces inventory waste and the carbon footprint associated with storing and transporting unsold goods. My own studio operates on this principle; I only print a custom piece once a client has commissioned it.

Furthermore, the additive nature of 3D printing means that material is only added where it’s needed, resulting in significantly less material waste compared to subtractive methods like cutting fabric from a bolt.

Any scraps or failed prints from my studio are collected and, whenever possible, recycled back into new filament, creating a truly circular process. This lean manufacturing approach is a game-changer for reducing fashion’s environmental burden.

2. Pioneering Recycled and Biodegradable Materials

The innovation in sustainable 3D printing materials is truly breathtaking. Beyond the traditional petroleum-based plastics, we’re seeing an exciting proliferation of filaments derived from recycled sources (like rPET from plastic bottles or rABS from industrial waste) and biodegradable options (like various forms of PLA and even experimental materials from agricultural waste).

My personal experiments with these emerging materials have shown immense promise, despite some initial printing challenges. While mass adoption is still a journey, the continuous research and development in this area are paving the way for a fashion industry that is not only beautiful but also responsible.

Imagine a future where a designer can choose a filament derived from a specific waste stream, designing a garment that is not only stylish but also tells a powerful story of sustainability and resourcefulness.

This kind of material innovation holds the key to a truly green fashion revolution.

Navigating the Challenges: What I’ve Learned the Hard Way

While the allure of 3D-printed fashion is undeniable, my journey has been far from a seamless glide. I’ve faced my share of headaches, missteps, and outright failures, each one a valuable lesson learned.

It’s important to be realistic about the hurdles you’ll encounter, because understanding them is the first step to overcoming them. From unexpected material quirks to design complexities, the path to creating stunning 3D-printed garments is paved with problem-solving.

My early days were a blur of troubleshooting, trying to figure out why a print was failing halfway through or why a supposed flexible filament felt like concrete.

These experiences, though frustrating at the time, have sharpened my skills and deepened my understanding of the entire process, making me a more resilient and resourceful designer.

1. The Unpredictability of Materials and Printers

Despite all the advancements, 3D printing still carries a degree of unpredictability, especially when working with new or experimental materials. I’ve had perfectly calibrated printers suddenly start acting up, seemingly for no reason, resulting in warped prints or nozzle clogs.

Materials, even from the same batch, can sometimes behave differently, affected by humidity, ambient temperature, or subtle variations in their composition.

I recall a specific incident where a batch of supposedly flexible TPU became unusually brittle after printing, shattering my expectations for a delicate, flowing skirt.

It taught me the importance of rigorous testing, printing small swatches and stress-testing them before committing to a full-scale garment. This constant need for calibration and adaptation is a significant challenge, requiring a blend of technical expertise and intuitive problem-solving that only comes with extensive hands-on experience.

It’s a delicate dance between machine and material.

2. The Steep Learning Curve of Design for Additive Manufacturing

Designing for 3D printing, especially for fashion, is fundamentally different from traditional design. It requires a completely new way of thinking about structure, movement, and assembly.

My early designs, though aesthetically pleasing in a 2D sketch, often failed miserably when translated into a 3D model intended for printing. I had to unlearn many conventional design principles and embrace the unique constraints and freedoms of additive manufacturing.

Understanding concepts like overhangs, support structures, resolution limitations, and how specific materials behave under different stresses is crucial.

For instance, creating intricate, interconnected links for a flexible garment demands a level of precision and foresight that goes beyond mere artistic vision; it requires an engineering mindset.

This steep learning curve is perhaps the most significant hurdle for new entrants, but it’s also where the most innovative solutions emerge from constant iteration and dedicated practice.

The Future is Woven: Emerging Trends and Revolutionary Innovations

As someone deeply immersed in the world of 3D-printed fashion, I can confidently say we are just scratching the surface of what’s possible. The pace of innovation is breathtaking, with new materials, printing technologies, and design philosophies emerging constantly.

I’m incredibly excited about the trajectory we’re on, moving beyond novelty into genuinely functional and integrated fashion solutions. From hyper-customized shoes that perfectly mold to your foot to garments that change color or even generate energy, the future of fashion is being printed, one layer at a time.

My personal vision for the industry is one where 3D printing democratizes access to bespoke fashion, making personalized, sustainable garments available to a wider audience, not just the elite few.

1. Multi-Material and Integrated Electronics

One of the most thrilling frontiers in 3D printing is the development of multi-material printing capabilities. Imagine a single garment that seamlessly integrates flexible and rigid sections, or even conductive pathways for embedded electronics, all printed in one go.

My mind races with the possibilities: dresses that light up in response to music, smart activewear that monitors vital signs directly within the fabric, or accessories that double as functional interfaces.

While still largely in the research phase, technologies like multi-extrusion FDM printers and specialized multi-material resin systems are paving the way.

I’ve seen prototypes that are truly mind-bending, blurring the lines between fashion, technology, and functionality. This integration could lead to truly “smart” garments that offer unparalleled interactivity and personalization, moving beyond mere aesthetics to become extensions of our digital lives.

2. Automation and On-Demand Customization

The ultimate goal for many in the 3D-printed fashion space is full automation and hyper-customization at scale. Imagine walking into a store, having your body scanned, and a bespoke garment being printed for you on the spot, perfectly tailored to your measurements and design preferences.

Robotic assembly systems are also being developed to handle the post-processing and assembly of complex multi-part garments, further streamlining the workflow.

While we’re not quite there yet, the continuous advancements in robotics, AI-driven design, and material science are rapidly closing the gap. This level of automation has the potential to completely disrupt traditional supply chains, offering unprecedented speed, customization, and sustainable localized production.

For me, this vision represents the true promise of 3D printing in fashion: a future where unique, perfectly fitting, and responsibly made garments are the norm, not the exception.

Wrapping Up

As I look back on my journey with 3D-printed fashion, it’s clear this isn’t just a niche; it’s a vibrant, evolving landscape where art, engineering, and sustainability beautifully converge.

From the initial spark of a digital design to the tactile joy of a finished garment, every step is a testament to innovation and persistence. I’ve found that the true magic lies not just in the technology, but in the dedication to push boundaries, learn from failures, and embrace the endless possibilities this revolutionary field offers.

It’s a space where creativity knows no bounds, and I can’t wait to see what incredible forms fashion takes next, layer by printed layer.

Useful Information to Know

1. Start with Small Projects: Don’t attempt a full garment on your first print. Begin with accessories, jewelry, or small structural components to understand your printer, materials, and design workflow. Learn by doing, but on a manageable scale.

2. Invest in Quality Filaments & Test Them: Cheap filament can lead to endless frustration. Prioritize reputable brands and always print small test swatches to assess flexibility, durability, and comfort before committing to a larger design. My experience taught me that material consistency is key.

3. Join a Community: The 3D printing and fashion tech communities are incredibly supportive. Online forums, local meetups, and social media groups are invaluable resources for troubleshooting, sharing tips, and discovering new techniques. I’ve learned so much from fellow enthusiasts.

4. Master Your Design Software: While 3D printing is fascinating, the foundation is your digital model. Become proficient in CAD software like Fusion 360 or Blender. Understanding mesh integrity, tolerances, and segmentation will save countless hours of failed prints.

5. Embrace Post-Processing: Don’t view printing as the end. Post-processing is where a printed piece transforms into a high-fashion item. Invest in good tools for sanding, smoothing, and dyeing. It’s often the difference between a prototype and a masterpiece.

Key Takeaways

The journey into 3D-printed fashion is a deeply rewarding blend of art, engineering, and innovation. It demands patience, continuous learning, and a willingness to overcome technical challenges, especially concerning material science and design for additive manufacturing.

Sustainability is a powerful driver, pushing designers towards eco-conscious materials and on-demand production. Ultimately, this field is on the cusp of revolutionizing how we create, consume, and interact with fashion, promising a future of unparalleled customization and responsible design.

Frequently Asked Questions (FAQ) 📖

Q: The text mentions navigating a ‘labyrinth’ when trying to create 3D-printed garments. From your direct experience, what are some of the most frustrating practical hurdles designers face in actually bringing these complex concepts to life?

A: Oh, where do I even begin? It’s not just a theoretical maze; it’s a very real, tangible headache when you’re on the ground trying to make something. For me, and I’ve seen this with others, the sheer unpredictability of materials is a huge one.

You might have a vision, a perfect CAD model, but then you pick a filament or resin, and it either doesn’t behave as expected, or worse, it crumbles after printing – that’s just soul-crushing.

Then there’s the design-to-print translation; what looks fantastic on screen can be an absolute nightmare for the printer, leading to failed prints that waste hours, days, and a lot of expensive material.

And don’t even get me started on the workflow itself – it can feel so piecemeal, going from design software to slicing to printer, often with different platforms that don’t speak to each other.

It’s like trying to conduct an orchestra where half the musicians are playing different scores. That inefficiency, that clunkiness, is where you lose so much time and just want to throw your hands up.

Q: Despite these significant hurdles you’ve personally experienced, what makes 3D printing in fashion so ‘tantalizing’ for both designers and consumers, and why isn’t simply owning a high-tech printer enough to succeed?

A: Honestly, it’s the sheer promise of it all that keeps you pushing through the frustrations. For designers, the hyper-customization aspect is a dream. Imagine crafting a piece that fits a specific person’s unique form perfectly, or realizing intricate, impossible-to-sew textures that just pop.

And for consumers, who are increasingly savvy and eco-conscious, the idea of a truly unique, on-demand, sustainable garment is incredibly appealing. No more mass production waste, just bespoke beauty.

But you’re right, simply having the latest, shinest printer on your desk is a bit like buying a grand piano and expecting to play a concerto without ever learning the notes.

The hardware is just one piece of a much larger, intricate puzzle. It’s about understanding material science, mastering advanced design software, knowing how to optimize a model for additive manufacturing, troubleshooting print issues, and then, crucially, integrating all of these disparate skills into a smooth, repeatable process.

The real magic happens when you understand how to wield the technology, not just own it.

Q: The article concludes by emphasizing that unlocking potential isn’t about the printer, but ‘mastering the process.’ From your perspective, what specific areas or approaches should designers focus on to truly streamline the journey from initial concept to a ‘stunning piece’?

A: Mastering the process, for me, boils down to a few key areas that often get overlooked in the excitement of new tech. First, design for additive manufacturing from the very beginning.

Don’t just design something cool and then hope it prints well. Think about layer orientation, support structures, material properties, and stress points during your initial sketching and CAD work.

This foresight saves endless headaches later. Second, deep dive into materials science. Don’t just pick the popular filament.

Understand its strengths, weaknesses, flexibility, and how it reacts to heat and stress. Experiment, keep detailed notes, and build your own material library.

Third, optimize your workflow relentlessly. This means finding software solutions that communicate well, creating templates for common tasks, and truly understanding your printer’s limitations and capabilities.

It’s about creating a repeatable pipeline from concept to finished product, even if that pipeline needs to be tweaked for each unique piece. Ultimately, it’s about treating the entire creation process as an integrated system, not just a series of disconnected steps.

When you connect those dots, that’s when a ‘stunning piece’ becomes a tangible reality, not just a fleeting vision.

📚 References

Wikipedia Encyclopedia

구글 검색 결과

구글 검색 결과

구글 검색 결과

구글 검색 결과

구글 검색 결과