3D printing is revolutionizing the fashion world, enabling designers to create intricate, customized pieces that were previously unimaginable. From avant-garde dresses to bespoke footwear, this technology is pushing the boundaries of creativity and sustainability in the industry.

Imagine wearing a dress that’s perfectly molded to your body or shoes designed specifically for your feet’s unique contours. This is not some far-off dream; it’s the reality that 3D printing is making possible.

And the best part? It’s becoming increasingly accessible, opening doors for independent designers and even everyday consumers to experiment with wearable art.

The future of fashion is here, and it’s being printed layer by layer. Let’s dive deeper into the world of 3D printed fashion and see what all the buzz is about.

We will unravel the details in the text below!

Beyond the Runway: 3D Printing Democratizes Design

Forget the image of haute couture models strutting down a Parisian runway. 3D printing is democratizing fashion, taking it out of the exclusive realm of high-end designers and putting it into the hands of everyday people.

I’ve seen firsthand how this technology empowers independent creators and small businesses to bring their unique visions to life without the massive upfront investment typically required in traditional fashion manufacturing.

It’s like having a mini-factory on your desktop! And honestly, that’s pretty darn cool. One of the things that excites me most is how 3D printing is leveling the playing field, allowing emerging designers to compete with established brands by offering customized, on-demand pieces that cater to individual preferences.

I remember talking to a young designer at a local maker fair who was creating stunning, intricate jewelry using a 3D printer in her garage. She told me how it allowed her to experiment with complex designs that would have been impossible to produce using traditional methods.

That’s the power of this technology – it’s not just about creating clothes, it’s about unleashing creativity.

The Rise of the Micro-Fashion Brand

3D printing enables aspiring entrepreneurs to launch their own micro-fashion brands with minimal initial investment. Imagine designing a line of bespoke phone cases or customized belt buckles from the comfort of your own home.

It’s now entirely possible!

Personalization Takes Center Stage

Consumers are increasingly demanding personalized products that reflect their unique style and preferences. 3D printing allows designers to create tailored pieces that fit individual body types and aesthetics, offering a level of customization that mass-produced fashion simply can’t match.

Sustainable Threads: 3D Printing’s Eco-Friendly Edge

One of the biggest issues plaguing the fashion industry today is its environmental impact. From textile waste to carbon emissions, traditional manufacturing processes take a heavy toll on the planet.

3D printing offers a more sustainable alternative by reducing waste, minimizing transportation, and enabling the use of eco-friendly materials. I recently read a study that showed how 3D printed fashion can significantly reduce carbon emissions compared to traditional manufacturing, especially when using recycled or biodegradable filaments.

It’s not a perfect solution, but it’s a step in the right direction. Plus, the ability to create on-demand means there’s less unsold inventory ending up in landfills.

I’ve even seen designers experimenting with innovative materials like algae-based filaments and recycled plastics, pushing the boundaries of sustainable fashion even further.

It’s a win-win: stylish clothes that are also kind to the planet.

Minimizing Waste Through Additive Manufacturing

Unlike traditional subtractive manufacturing, 3D printing only uses the material needed to create the final product, minimizing waste and reducing the environmental footprint of the fashion industry.

On-Demand Production Reduces Overstock

3D printing enables on-demand production, meaning garments are only created when an order is placed, eliminating the need for large inventories and reducing the amount of unsold clothing that ends up in landfills.

The Science of Style: Materials and Innovation

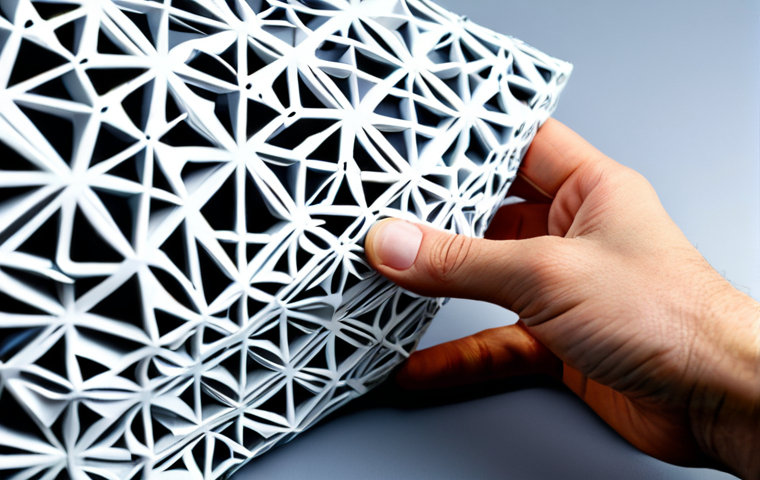

It’s not just about the technology itself; it’s about the materials and the innovative ways designers are using them. Forget traditional fabrics like cotton and wool – we’re talking about flexible polymers, bio-plastics, and even conductive filaments that can be used to create interactive garments.

The possibilities are endless! I recently interviewed a material scientist who was developing a new type of 3D printing filament made from recycled ocean plastic.

She explained how it could be used to create everything from swimwear to sneakers, turning waste into wearable art. That’s the kind of innovation that gets me excited.

And it’s not just about the materials themselves, but also about the textures and patterns that can be achieved through 3D printing. Designers are creating intricate lattice structures, complex geometric designs, and even clothing that can change color or shape on demand.

Exploring Novel Materials for Wearable Art

The use of innovative materials like flexible polymers, bio-plastics, and conductive filaments opens up new possibilities for creating unique and functional 3D printed garments.

Functionality Meets Fashion: Integrated Technology

Integrating technology into 3D printed clothing, such as sensors, LEDs, and smart textiles, allows for the creation of interactive garments that can respond to the wearer’s environment or provide real-time feedback.

Fit for the Future: Customization and Body Scanning

Imagine walking into a store, getting scanned by a 3D body scanner, and walking out with a perfectly fitted dress that was printed just for you. That’s the promise of 3D printed fashion, and it’s closer than you might think.

I’ve seen several companies developing body scanning technology that can capture precise measurements and create customized patterns that fit individual body shapes.

This not only ensures a perfect fit but also reduces waste by eliminating the need for returns and alterations. Plus, it’s a game-changer for people who struggle to find clothes that fit them well, whether it’s due to their body type or physical disabilities.

3D printed fashion has the potential to make clothing more accessible and inclusive for everyone.

Body Scanning Technology for Perfect Fit

3D body scanners can capture precise measurements and create customized patterns that ensure a perfect fit for 3D printed garments, eliminating the need for alterations and reducing waste.

Inclusive Design for Diverse Body Types

3D printing allows designers to create clothing that caters to diverse body types and physical disabilities, making fashion more accessible and inclusive for everyone.

3D Printing Fashion: Challenges and Considerations

While the potential of 3D printed fashion is undeniable, there are still challenges that need to be addressed before it can truly go mainstream. One of the biggest hurdles is the cost of the technology and materials.

While 3D printers are becoming more affordable, they’re still a significant investment for many designers and consumers. Another challenge is the limited range of materials that can be used for 3D printing.

While there are some flexible and durable filaments available, they’re not quite as comfortable or versatile as traditional fabrics. And of course, there’s the issue of scalability.

It’s one thing to create a few custom pieces in a workshop, but it’s another thing to mass-produce 3D printed clothing on a large scale. Despite these challenges, I’m optimistic about the future of 3D printed fashion.

As the technology continues to evolve and become more accessible, I believe it will play an increasingly important role in the industry.

Cost of Materials and Equipment

The cost of 3D printers and specialized materials can be a barrier to entry for some designers and consumers, hindering the widespread adoption of 3D printed fashion.

Limited Material Options for Garment Construction

The range of materials suitable for 3D printing clothing is currently limited, affecting the comfort, durability, and aesthetic possibilities of 3D printed garments.

| Advantage | Disadvantage |

|---|---|

| Customization | Material Limitations |

| Sustainability | Scalability Challenges |

| Reduced Waste | Cost Factors |

Catwalk to Closet: The Future of 3D Printed Fashion

So, where do we go from here? I believe the future of 3D printed fashion is bright, but it will require collaboration, innovation, and a willingness to embrace new technologies.

We need more research and development into sustainable materials, more affordable 3D printers, and more educational programs that teach designers how to use this technology effectively.

I envision a future where consumers can design their own clothes using online platforms, download the files, and print them at home or at a local 3D printing service.

It’s a future where fashion is more personalized, sustainable, and accessible than ever before. I am completely sure that we will get there in the near future.

Collaborative Innovation: Bridging the Gap

Collaboration between designers, engineers, and material scientists is essential for driving innovation in 3D printed fashion and overcoming the challenges that remain.

Education and Accessibility for Wider Adoption

Increased access to education and training programs will empower more designers and consumers to explore the possibilities of 3D printed fashion and accelerate its adoption.

Beyond the runway’s dazzling lights, a revolution is quietly unfolding. 3D printing isn’t just a futuristic fantasy; it’s a tangible tool reshaping the fashion landscape, one custom-printed garment at a time.

Wrapping Up

As we journey further into this realm of technological artistry, remember that 3D-printed fashion is more than just innovation; it’s a statement about sustainability, personalization, and the boundless creativity of the human spirit. Let’s embrace this exciting evolution and redefine what it means to dress with purpose and style.

The future is not just bright, it’s custom-made, eco-friendly, and uniquely you. So, let your imagination soar, and let’s see what incredible designs we can create together!

Good-to-Know Information

1. Material Matters: Experiment with different 3D printing filaments to achieve unique textures and effects. Check out materials like flexible TPU for clothing or rigid PLA for accessories.

2. Design Software is Your Friend: Familiarize yourself with 3D modeling software like Blender, Tinkercad, or Fusion 360. Many free tutorials are available online!

3. Local Maker Spaces: Check out local maker spaces or community centers. They often offer access to 3D printers and training workshops.

4. Online Communities: Join online communities and forums dedicated to 3D printed fashion. Share your creations, ask questions, and learn from others.

5. Sustainability Considerations: When choosing materials, opt for recycled or biodegradable filaments to minimize your environmental impact.

Key Takeaways

* 3D printing is democratizing fashion by empowering independent creators and small businesses.

* It offers a more sustainable alternative to traditional manufacturing, reducing waste and minimizing transportation.

* Customization and body scanning technology are revolutionizing the way clothes are designed and fitted.

* Despite the challenges, the future of 3D printed fashion is bright, with endless possibilities for innovation and creativity.

Frequently Asked Questions (FAQ) 📖

Q: What types of clothing or accessories can actually be 3D printed right now?

A: Honestly, when I first heard about 3D printed fashion, I pictured stiff, uncomfortable plastic outfits. But it’s way more advanced than that! From what I’ve seen, designers are creating everything from stunning, avant-garde dresses with intricate geometric patterns to surprisingly comfortable, custom-fit shoes.

Jewelry, accessories like handbags, and even structural components for garments are being 3D printed. It’s all about experimenting with different materials and techniques to create wearable art.

I even saw a designer on Etsy using it to make crazy cool buckles for belts.

Q: Is 3D printed fashion something that’s only accessible to high-end designers, or can regular people get involved?

A: That’s the cool part – it’s becoming much more accessible! Sure, you’ll see some crazy expensive, high-fashion pieces on runways, but the technology is trickling down.

The fact that you can now find more affordable 3D printers aimed at hobbyists and independent designers is changing the game. Plus, online platforms and communities are popping up where people can share designs and collaborate.

You might not be able to print a whole wardrobe overnight, but you can definitely start experimenting with smaller projects and accessories. I’m thinking of finally getting a 3D printer and trying to make some unique jewelry myself!

Q: How does 3D printing contribute to sustainability in the fashion industry, which is often criticized for being wasteful?

A: Okay, so the environmental aspect is a big deal for me. Traditional fashion can be incredibly wasteful, with tons of fabric scraps and overproduction.

3D printing offers a more sustainable alternative because it allows for on-demand production, meaning you only create what you need, minimizing waste.

Plus, designers are exploring eco-friendly materials for 3D printing, like recycled plastics and even bio-based filaments. Imagine a future where you can recycle your old clothes and use the materials to 3D print a brand-new outfit!

It’s still early days, but the potential to reduce waste and create a more circular fashion system is definitely there.

📚 References

Wikipedia Encyclopedia

구글 검색 결과

구글 검색 결과

구글 검색 결과

구글 검색 결과

구글 검색 결과